Galvanized Steel Coils

Key Features

- Galvanized Steel Coil is used cold rolled steel coil as substrates by a continuous hot-dip process. This method tightly adheres the coating to the steel with an iron-zinc alloy bonding layer formed by a diffusion process while the heated steel strip is in contact with the molten zinc.

Terms of price: EXW, FOB, CFR, CIF

Product customization available

Advatage

- Available Standards— ASTM, AISI, JIS, ISO, EN, BS, GB,

- Surface— Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

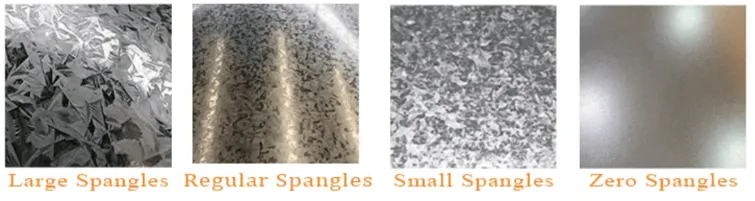

- Spangle— Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

- Surface structure— Zero or nomal spangle

- Width— 20-2800mm

- Tolerance — ±10%

- A steel coil is a finished steel sheet or strip that has been coiled or wound after rolling with the width of the metal sheet being greater than its thickness. Steel coil with certain coatings can be weather-resistant, protect against moisture, and is eco-friendly. The steel coil is produced through different processes depending on the desired outcome.

Hot-rolled steel coil is the steel plate that is rolled at a high temperature, making the steel easier to manipulate. Due to the quick and easy process, hot-rolled steel saves time and is less expensive to manufacture.

Cold-rolled steel

coil has a nicer finish and is more durable than hot-rolled steel. Cold-rolling is a process where the steel is rolled at room temperature, below its recrystallization temperature. While cold-rolled steel coil is superior to other coils, cold-rolled steel can be harder to manipulate due to the higher carbon content.Galvanized steel

coil is created through a hot-dipped process that dips the metal into zinc for a nice smooth coating. The coating creates a strong rust resistance and prolongs the life of the steel coils.Galvannealed steel coil is created similar to galvanized steel through a hot-dipping process that soaks the metal into a liquid bath of zin alloy and then is passed through in-line heat treatment. Galvannealed steel is usually thinner and is more assessable to painting compared to other processes.

Description

Surface Treatment Of Galvanized Steel Coil

| Surface treatment type | Code | Feature |

| Chromic acid treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | It has certain corrosion resistance, good paint performance, and prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | Have certain corrosion resistance, good paint performance, and prevent rust |

| Oiled | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate painting |

Chromate treatment of galvanized steel coils is also called passivation treatment. Through passivation treatment, the surface structure and gloss of the galvanized layer can be improved, the corrosion resistance and service life of the galvanized layer can be improved, and the bonding force of the coating and the base metal can be improved.

The purpose of oiling galvanized steel coils is a protective layer is formed on the surface of the steel coil to prevent the surface from rusting.

Galvanized Steel Coil Applications

Galvanized steel coil is widely used due to its long-lasting anti-corrosion properties. Common applications include home appliances, roof sheets, and automotive panels.

Car Board

Automotive plates are shaped through stamping.

Roof Sheet

Key performance metrics include tensile strength and coating quality. Learn more about PPGI and PPGL.

Home Appliances

Used in devices like air conditioners and refrigerators.

Substrate

Serves as a base for prepainted steel coils, offering enhanced durability.

Wukuang Steel offers a variety of galvanized coil sizes with fast worldwide delivery.Wukuang for your needs.

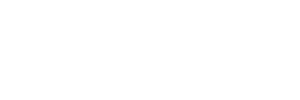

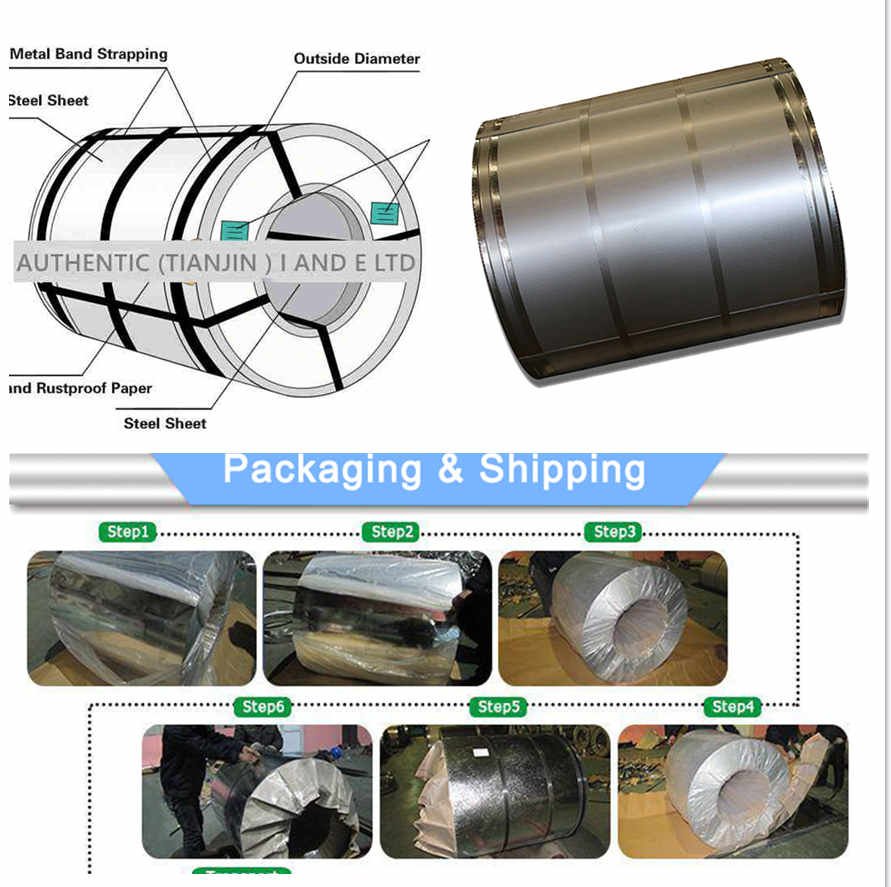

Product Packing

FAQ

Galvanized steel coil could be oiled?

Yes, it could be oiled. 8-20g per square meters. Oiling can prevent the oxidation of galvanized sheets in a short time.

Do you accept the test of zinc coating or not?

Yes, accept the test of zinc coating. We could send galvanized steel coil samples to the laboratory that the clients required. Or Chinese SGS.

Will galvanized steel coils rust?

Galvanized steel takes a long time to rust, but it will eventually rust. This type is carbon steel that has been galvanized or coated with a thin layer of zinc. The zinc acts as a barrier preventing oxygen and water from reaching the steel, providing advanced corrosion protection.

How do you control quality?

Mill Test Certification is supplied with shipment, Third Party Inspection is available. and we also get ISO,SGS. View more about our top 6 services>>

How to get samples?

FREE samples are available for your checking and testing. And to get free samples, please email us today, courier cost will be paid in your side.

Get in touch

Contact our sales

Appointment

Let's start your project

Related Products