Stainless Steel Coil

Key Features

Wukuang Steel has a large and diversified inventory of stainless steel coil (roll) in a wide range of grades, gauges, tempers, and finishes, allowing us to provide a broad range of products to our customers.

Advatage

Our stainless steel coils are available in various sizes, and are available in custom cut sizes to meet your individual requirements.

Stainless Steel Features:

- Available Grades — 301, 302, 303, 304316/316L, etc

- Available Standards— ASTM, AISI, JIS, ISO, EN, BS, GB,

- Available Finishes— No.1, 2D, 2B, BA, 3, No.4, No.240, No.320, No.400, HL, No.7, or as your Request

- Custom process— Bending, Welding, Decoiling, Cutting, Punching, Polishing, or as your Request

- Width(mm)— 3mm – 2000mm, or as your Request

- Thickness(mm)— 0.1mm – 3mm; 3mm – 200mm, or as your Request

- Thickness tolerance(mm)— ±0.1mm

Popular applications of stainless steel coil include chemical equipment and piping, heat exchanger components, dairy and food handling equipment and utensils, cryogenic vessels and components, and architectural and structural applications exposed to non-marine atmospheres.

What is Steel Coil Slitting?

Stainless steel rolling mills reduce coils to various thicknesses and widths. Once you arrive at the desired thickness the coil is then slit-to-width through a process known as steel coil slitting.

Steel coil slitting is a metal cutting process where large rolls or coils of sheet metal are cut using very sharp rotary blades. To achieve straight lines, they are cut length-wise into the large coil, creating narrower strips. Circular blades are responsible for making the cuts as the coil runs through the slitter. These are known as “knives” and can be moved to provide for varying widths.

Stainless steel can be slit into many different widths. Every application requires its own stainless steel coil slitting capability. Stainless steel slitting proficiencies mean that all materials sent in to slit are done so according to the exact qualifications that are necessary for that particular job.

A slitting machine has three main parts: an uncoiler, the slitter, and a recoiler. All elements must be perfectly aligned to ensure the success of the material. Factors such as knife clearance and cutter spacing must be calculated and aligned. It is critical that quality tooling and sharp knives are all in place for the job to be done correctly.

Stainless Steel Slitting involves minimum burr, minimum camber, and maximum flatness.

Surface Finish

| Technique | Surface Finish | Grade Series | Thickness(mm) |

| Hot Rolled | No.1 / 2E | 201/304/316L | 2.2-12.0 |

| Cold Rolled | 2B | 201/304/316L | 0.25-3.0 |

| Cold Rolled | 2B | 410S/430 | 410S/430 |

| Cold Rolled | No.4 /Hairline | 201/304/316L | 0.22-3.0 |

| Cold Rolled | Mirror / Linen | 201/304/316L | 0.22-3.0 |

| Cold Rolled | SB | 410S/430 | 410S/430 |

| Cold Rolled | BA | 201/304 | 0.2–1.8 |

| Cold Rolled | BA | 410S/430 | 410S/430 |

| Cold Rolled | 2BA | 304/410S/430 | 0.25-2.0 |

What Are The Grades of Stainless Steel Coils?

| Austenitic Stainless Steel | 201, 301, 303, 304, 304L, 309S, 310S, 316/316L, 321, 347, 904L, etc |

| Martensitic Stainless Steel | 410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc |

| Duplex Stainless Steel | S31803, S32101, S32205, S32304, S32750, etc |

| Ferritic Stainless Steel | 429, 430, 433, 434, 435, 436, 439, etc |

Stainless Steel Coil Applications

- Food Processing and handling

- Heat exchangers

- Chemical process vessels

- Conveyors

- Architectural

- Marine

- Pharmaceutical equipment

Qinghe Steel stocks a wide range of stainless steel coil sizes for your specific project needs. We offer quick delivery throughout the world. Contact us today to discuss stainless steel coil for your project needs.

- No. 2D – A smooth, non-reflective cold-rolled annealed and pickled or descaled finish.

- No. 2B – A smooth, moderately reflective cold-rolled annealed and pickled or descaled finish typically produced by imparting a final light cold-rolled pass using [large diameter] polished rolls.

- Bright Annealed [BA] Finish- A smooth, bright, reflective finish typically produced by cold rolling followed by annealing in a protective atmosphere so as to prevent oxidation and scaling during annealing.

- No. 3 Finish is characterized by short, coarse, parallel polishing lines, which extend uniformly along the length of the coil.

- No.4 Finish is characterized by short, parallel polishing lines, which extend uniformly along the length of the coil. It is obtained by mechanically polishing a No. 3 finish with gradually finer abrasives.

- No.7 Finish has a high degree of reflectivity and a mirror-like appearance. A No. 4 finish that has been polished to 320-grit is buffed for up to 10 minutes but existing grit lines are not removed. The remnants of fine polishing lines can generally seen by an observer standing several feet from a panel.

- No.8 Finish It is produced in the same manner as the No. 7 finish except that the buffing is continued for an additional five to ten minutes. In comparison to a No. 7 finish, the grit lines are much less visible, but they can be seen if the finish is examined closely. The resulting finish is mirror-like but not a perfect mirror.

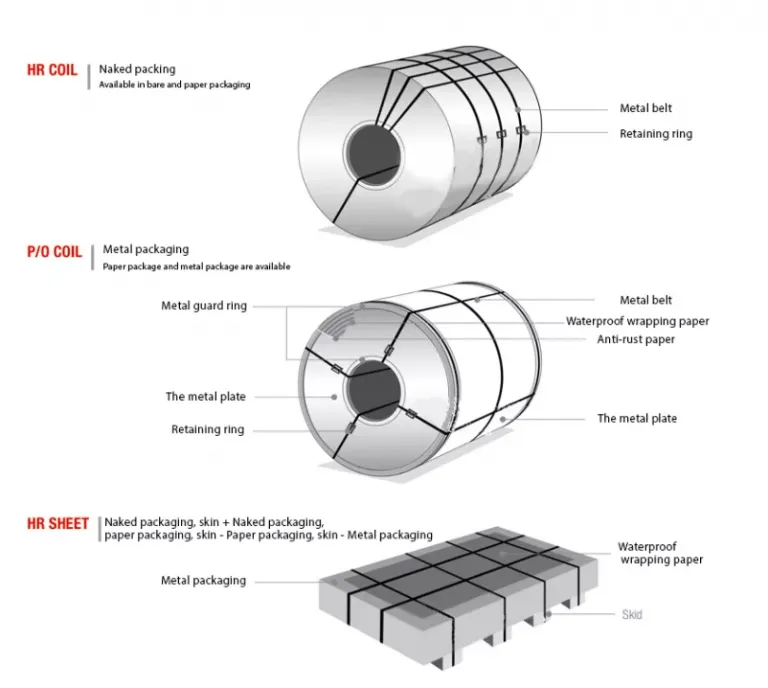

What Is The Packaging Standard of Stainless Steel Coils?

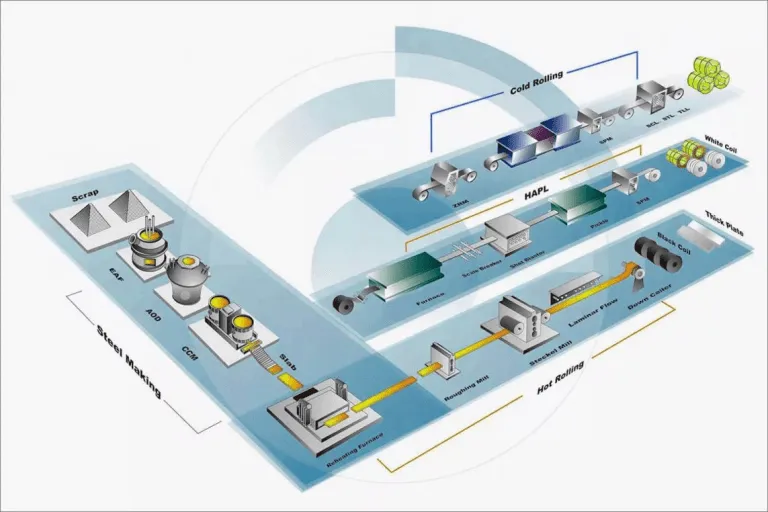

How Stainless Steel Coils Are Made?

Stainless steel coils are the most widely used type of metal coil in the market. They are mainly used for making pipes, tubes and sheets. These stainless steel coils are manufactured using different types of raw materials and advanced technology.

Stainless steel coils are made using several processes like hot rolling, cold rolling and extrusion. The process of making these coils depends on their thickness, diameter, length and width. The most common process used to manufacture stainless steel coils is hot rolling process. It involves melting the raw material at high temperature and then shaping it into desired forms by rolling them through a series of rollers that have varying degrees of hardness. This process results in producing large sized products with a uniform thickness, size and shape.

The second commonly used process is cold rolling process which is carried out under controlled conditions so as to maintain product quality during production stages. In this process, the material undergoes three processes namely roughing pass (first pass), semi-finishing pass (second pass) and finishing pass (third pass). This method produces products with high dimensional accuracy and good surface finish with low yield loss due to less friction during rolling process

Get in touch

Contact our sales

Appointment

Let's start your project

Related Products