PPGI PPGL Coil

Key Features

PPGL sheets and coils are coated with zinc, silicon, and aluminum, containing at least 55% aluminum and 43.5% zinc, along with silicon and other elements.

Pre-Painted Galvanized Steel (PPGI) is coated with molten zinc, providing protective properties that make it ideal for roofing.

Price terms: EXW, FOB, CFR, CIF

Product customization is available.

Advatage

- Thickness — 0.12 mm-1.2 mm

- Overall Width — 600 mm-1,250 mm

- Coatings — PE, SMP, HDP, PVDF

- Coating Thickness — Top: 11-35 μm Back: 5-14 μm

- Colors — As per RAL Color (custom patterns are available)

- Monthly Production — 5,000-10,000 tons

- Value-added Services — Custom sample, slitting, cutting, stamping, bending, profiling, and other processing services

- Available Standard – – ASTM, EN, JIS, GB, etc

Overview

PPGI Coils exhibit high degrees of strength and dimensional accuracy for use in various manufacturing industries spanning a wide range of sectors as mentioned below:

- Roofing and Cladding (Single Skin)

- Sandwich Panel (Double Skin)

- Automatic Doors

- Farm Equipment, Greenhouses, Silos, Barns

- K Span

- Fencing

- Lighting

- Ceiling accessories

- Internal partition

- Cold Rooms, Shelves, Water Chillers, Water Coolers, Water Heaters & HVAC units

- Shipbuilding industry

- Vehicle manufacturing industry

- Home appliance industry

- Designing, Interior Cladding

- Steel furniture

- White & brown Goods

- Kitchen appliances such as Ovens, Ranges, Sinks, Kitchen Units, Shelves, Toilet Strands, and Cooker Wrapper

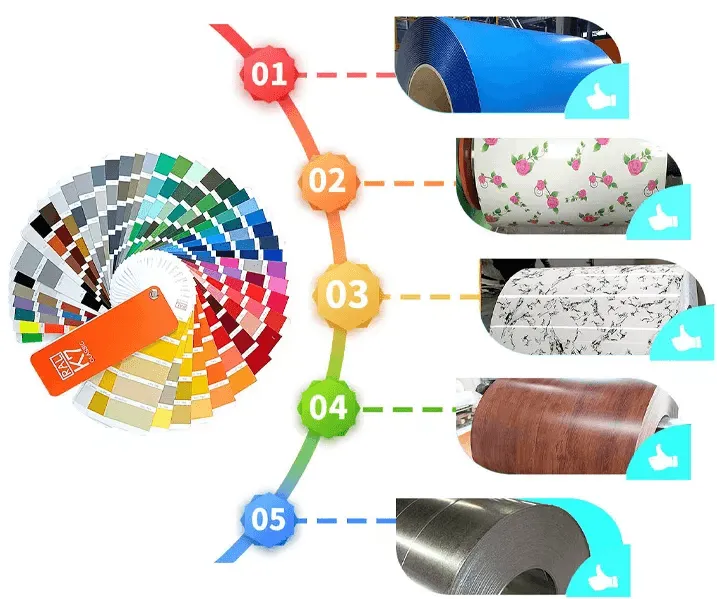

Popular Patterns

Rolls can be divided into straight hair rolls and finishing rolls (split rolls, flat rolls, and slit rolls). According to its material and performance, it can be divided into ordinary carbon structural steel, low alloy steel, and alloy steel. According to different uses, it can be divided into cold-forming steel, structural steel, automobile structural steel, corrosion-resistant structural steel, mechanical structural steel, welded gas cylinder and pressure vessel steel, pipeline steel, etc. View more about carbon steel.

Description

What's the Pre-Painted Galvalume Steel(PPGL)?

PPGL sheets and coils are processed by coating with zinc, silicon, and aluminium. More precisely, the ingredients of the galvalume steel sheet have at least 55% aluminium and 43.5% zinc, with the rest being silicon and other elements. PPGL sheets can be used as roofing in addition to chimney pipes or ovens owing to their corrosion resistance, good heat resistance, and surface conductivity.

According to the shape, we divide prepainted galvanized steel into coil and sheet.

Benefits of PPGL Sheet Coil

There are many benefits to purchasing pre-painted galvanized iron for your project, including: Any shape can be created such as curved, rectangular, oval and tubular. Available in a variety of color ranges to choose from Improve durability Provide convenient cleaning facilities affordable maintenance Tensile properties provide sufficient strength to cover roofs, awnings and sheds.

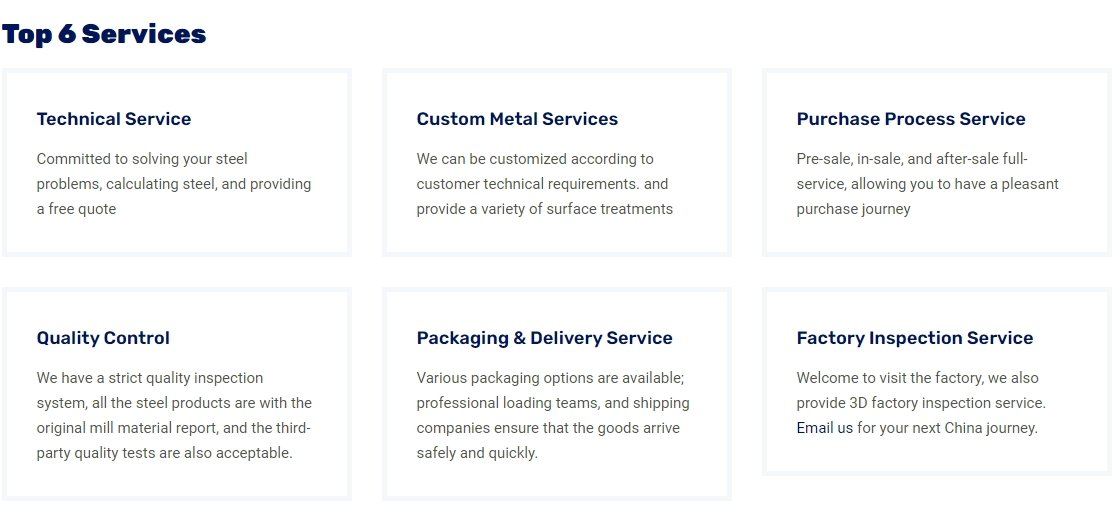

PPGL Sheet Coil Colors

The common colors include brick red, blue, green, grey, etc. Both glossy and matte colors are available. Also, there are different printed patterns to choose from, such as flower, grass, brick, wood grain, etc. You can also send us patterns for custom design. Pre-painted steel can be formed into almost any shape, and it has excellent resistance to weathering, superior longevity and texture options.

Typical top-coating materials

Epoxy

Regular Modified Polyester (Rmp)

Silicon Modified Polyester (Smp)

High Durable Polyester (Hdp)

Pvdf/Pvf2(Poly Vinylidene Fluoride)(p> Plastisol

Pupa / Ars

Anti-Bacterial

Self-Cleaning/ Anti Dust

Wrinkle Finish Anti Skidding

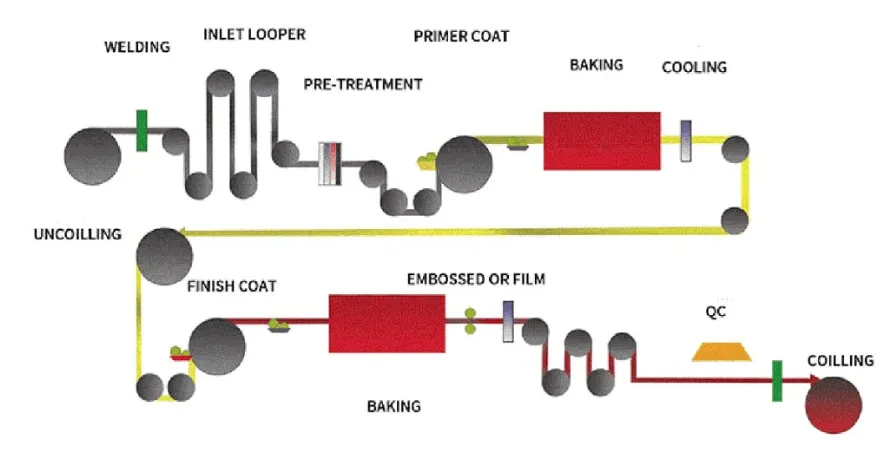

PPGL Sheet Coil Production Process

It is very similar to the manufacturing process of PPGI. It starts from uncoiling, welding, pretreatment, primer painting, baking, cooling, twice-painting, baking and cooling again, quality control, and coiling for sale.

Differences Between PPGI And PPGL

- Cost — PPGI sheets cost less than PPGL sheets.

- Various Base Metal — PPGL is with galvalume sheet as substrate, which is coated with 55% aluminum, 43.3% zinc, and also 1.6% silicon. This is the main distinction between PPGI as well as PPGL.

- Durability — PPGI sheets are poorly compared to PPGL sheets when exposed to natural influences such as water. PPGL sheets may last beyond 10 years in good condition. They do not easily rust and do well. The lifespan of PPGL is almost double that of PPGI.

- Thickness and weight — Generally, PPGI sheets are lighter than PPGL sheets. The thickness however is dependent on the coating applied.

- Finish — PPGL sheets possess a smoother finish in comparison with PPGI sheets which can be directly caused by the aluminum component in PPGL which PPGI sheets do not have.

- Corrosion resistance — PPGL sheets are more corrosion resistant. When a PPGL sheet is cut, its edges become exposed which makes it more vulnerable to corrosion. PPGI is quite likely to become corroded.

Wukuang Steel stocks a wide range of PPGL coils and PPGI sheet sizes for your specific project needs. We offer quick delivery throughout the world. to discuss PPGL coils and PPGI sheet for your project needs.

Get in touch

Contact our sales

Appointment

Let's start your project

Related Products